You ever have one of those moments where you’re halfway through vacuuming, feeling productive for once, and then the hose suddenly feels like it’s giving up? So you do the usual routine: pop the bin off, shake it a little, peek down the hose like you’re checking for wildlife. Maybe nudge the end of a broom handle in there, to make sure it didn’t somehow inhale a sock whole.

Everything looks fine. No jammed cereal pieces, no wads of dog or cat hair. The vacuum just… lost its will to participate.

And this is usually where people leap straight to the big, expensive conclusion: “Welp, the motor’s dead.” But a lot of the time, the motor is perfectly healthy. The real issue is usually something sneakier, some tiny place where air slipped loose and started taking the scenic route instead of going down the nozzle. A quick visit to your local vacuum repair shop can save you from a whole lot of guessing and YouTube-inspired disassembly.”

A vacuum is basically a controlled wind tunnel. As long as all the air is going where it’s supposed to, the thing is a beast. The moment even a sliver of air goes wandering off on its own? The suction at the carpet drops dramatically, and you’re left wondering why your vacuum cleaner suddenly has no suction.

Table of Contents

ToggleSome Possible Causes of Low/No Suction Without a Clog

1. Hose Micro-Tears (Possibly the Most Missed Failure)

Flexible hoses live a hard life. They twist, bend, get yanked around chair legs, dragged across tile grout, crushed under doors, stepped on during laundry runs—pretty much everything except treated gently.

After enough of that, the plastic starts to give. Not in a noticeable “look at this giant hole” way, but in little hairline splits that hide on the underside where you might, understandably, never think to look.

These tiny tears are troublemakers. They don’t whistle, they don’t flap open, they don’t announce themselves. But the vacuum motor doesn’t care about your detective work, it just follows the easiest airflow it can find. And that tiny split is the easy path.

So you end up with this confusing combination of symptoms:

- barely any pickup at the floor

- motor sounds totally normal

- nothing visibly clogged

- the occasional mysterious puff of dust near the handle

It feels like the vacuum is “weak,” but really it’s just inhaling from the wrong place. A tiny tear can steal a surprising amount of suction before you even know it exists.

How to check safely

Run the vacuum and gently flex the hose in sections. If suction changes or you feel air on your hand, you found the leak.

Do not tape it as a long-term fix. Tape changes airflow, collects debris, and often breaks loose into the system. Replacement hoses are designed to maintain internal diameter and airflow velocity, improvised patches are not.

If you do find a tear, it’s worth having your local vacuum repair shop take a look. A tech can easily confirm whether it’s just the hose or if the leak stressed anything else downstream. They can usually get you the exact compatible replacement part and make sure everything’s sealed up right, so you don’t end up with the same problem again a month from now.

2. Seal Leaks (The “It Still Seems to Run Fine” Problem)

Vacuums don’t get enough credit for how many little seals and gaskets they depend on. There’s the bin or bag door seal, the gasket around the filter housing, the O-rings that keep the wand snug, even the swivel seal in the floor head. All of them have one job: keep the airflow contained so the suction you paid for ends up at the carpet, not drifting around inside the machine.

But seals age. They dry out, flatten, shift slightly out of place — nothing dramatic, just enough to let room air slip in. And that tiny slip of air creates one of the most confusing symptoms out there:

the vacuum suction feels strong at the hose, but barely picks up anything at the floor.

From the outside, the machine sounds healthy. No clogs, no burning smell, no warning lights. Meanwhile, the pressure is escaping right before it reaches the nozzle, so the part that should be doing the cleaning barely gets any airflow at all.

The bigger issue is what happens inside. Once air starts leaking around a seal, dust can bypass the filter and settle in the motor housing. That’s how a perfectly good motor ends up wearing down long before its time.

And here’s where it gets tricky for DIY fixes: seal leaks often aren’t visible. Technicians usually diagnose them with smoke tests or pressure tools, for quick, precise checks that show exactly where the air is escaping.

If you suspect a seal problem, it’s worth letting a local vacuum repair shop take a look. It’s usually a simple, inexpensive fix when caught early, and it prevents the kind of slow, hidden damage that turns a small leak into a major repair.

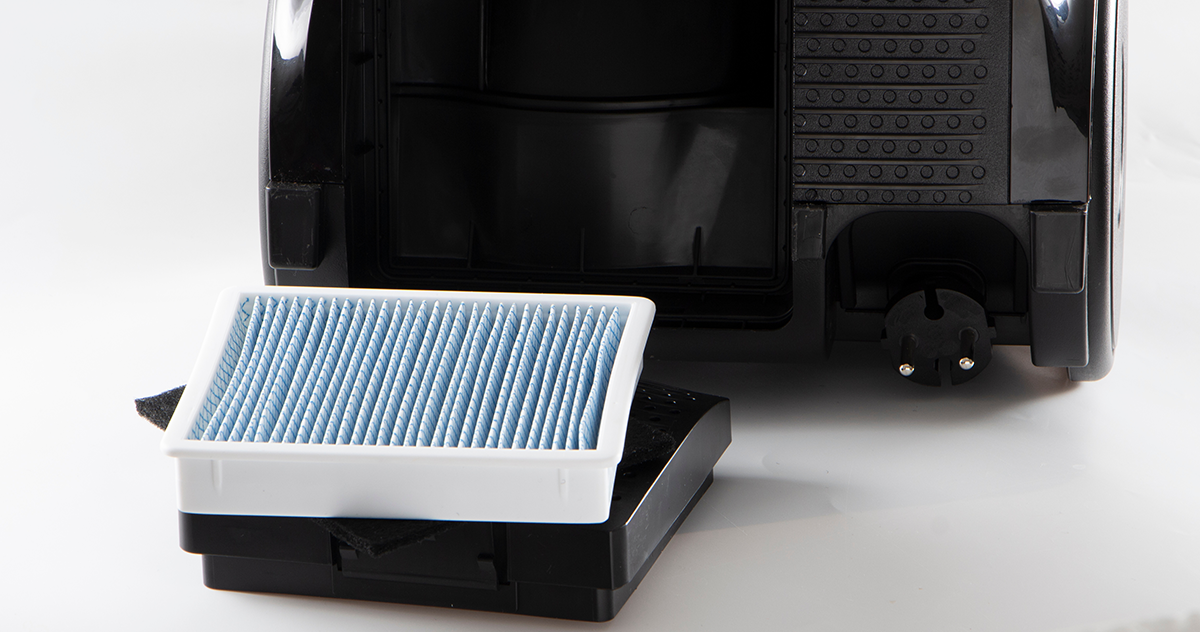

3. Saturated HEPA Filters (Even When They Look Clean)

A HEPA filter can be completely blocked without appearing dirty. Sometimes they can practically look spotless, bright white, barely a speck on them, and still be packed so tightly with fine dust that air can barely move through. All that microscopic debris burrows deep into the filter material, way past the point where a rinse or tap-out will do anything.

When that happens, the vacuum doesn’t quit outright. It just starts struggling.

You might notice things like:

- suction fading a little more each week

- the motor taking on a higher, strained pitch

- the bin filling normally even though the floor still looks dirty

- the body of the vacuum feeling warmer than it used to

It’s a slow decline, and because the filter looks clean, a lot of people don’t make the connection.

Washing doesn’t always save it, either. Once those microscopic pores are clogged, airflow is permanently restricted. And restricted airflow is the quiet killer here — the motor and electronics run hotter, work harder, and wear out faster. A lot of “mysterious” motor failures actually start with an overworked machine trying to breathe through a choked filter.

If your vacuum seems hotter, louder, or weaker despite having an “okay-looking” HEPA filter, it’s worth having a local vacuum repair shop check the airflow and confirm whether the filter needs replacing. A quick test can save a motor that’s on its last good days.

4. Bypass Air Leaks (Internal Air Path Separation)

Note: This is one that most owners cannot safely diagnose. Bypass leaks occur in internal ducts that aren’t visible from the outside. You can’t inspect them the way you can a hose or a gasket. The only way to confirm the issue is by opening the vacuum’s body, which is not designed for casual or DIY disassembly.

Inside every vacuum there are two separate air paths:

- One for the dirty air coming from the floor, and

- Another that feeds cooling air to the motor.

These paths aren’t supposed to meet, mingle, or share so much as a handshake.

But if an inner duct cracks, shifts, or pops loose, the vacuum starts pulling its own cooling air instead of the air you’re trying to clean. From the outside, the machine might sounds perfectly normal, or sometimes even louder, like it’s really working hard.

Typical symptoms look like this:

- almost no pickup at the floor

- warm air blowing from the body

- no visible clog anywhere

- motor noise that doesn’t match what the vacuum is (or isn’t) doing

Because all of this happens inside the machine, it’s nearly impossible to diagnose without opening the housing. And that’s where things get risky. Internal ducts sit right alongside wiring, seals, thermal cutoffs, grounding paths, all the stuff that keeps the vacuum safe to run. One misplaced screw or slightly misaligned gasket can let dust into the motor or disable the very parts designed to prevent overheating.

This is one of those repairs where a quick inspection at a local vacuum shop can save the day. They can spot the separation, reseat or replace the duct, and make sure everything goes back together the way the safety design intended, before a small internal leak becomes a burnt-out motor.

Why Suction Problems Rarely Resolve Without Repair

Airflow inside a vacuum is supposed to behave like a little sealed ecosystem. Everything moves in a loop, everything depends on everything else. Once a leak shows up or something starts restricting the path, the machine doesn’t shrug and work around it, it pushes harder. It runs hotter. It spins faster than it really should, trying to make up for air it’s no longer getting.

And that overwork adds up in weird, expensive ways:

- Housings can start to warp ever so slightly.

- Brushroll bearings get hot enough to soften.

- Safety cutoffs trip more and more often.

- Eventually the motor, which has been soldiering through all of this, hits its limit.

That’s how a vacuum cleaner can go from “something feels a little off” to “it won’t even turn on now” in a surprisingly short stretch of time.

When to Stop Troubleshooting at Home

Safe checks:

- replace the bag / empty the bin

- inspect hose exterior

- verify compatible replacement filters are installed correctly

Stop troubleshooting / experimenting when:

- the machine must be opened with tools

- wiring or internal ducts are involved

- the vacuum smells hot or electrical

- suction changes depending on how you hold it

At that point the risk shifts from cleaning performance to equipment damage or personal safety.

What a Vacuum Repair Shop Tests

A proper airflow diagnosis usually takes only a few minutes with the right equipment:

- sealed suction measurement

- airflow volume test

- leak detection across seals

- filter restriction testing

- motor load analysis

Instead of replacing random parts, the technician identifies where the air stopped moving, which is the real problem.

Many suction issues turn out to be small, inexpensive repairs once correctly located. Continuing to guess at home is what typically makes them expensive.

The Bottom Line

At the end of the day, when a vacuum suddenly loses suction and there’s no clog to blame, it’s usually just air sneaking out somewhere it shouldn’t be. A pinhole in the hose, a worn-out gasket, a HEPA filter that’s been quietly choking for months, or some internal seam that decided today was the day to let go.

And the tough part is, these aren’t problems you can strong-arm into behaving. You can clean the bin twice, shake the hose, wash the filters—none of it is going to convince the machine to seal itself again. Air leaks have to be found and fixed.

That’s why a quick visit to someone who does this every day can save a lot of stress, and a lot of money. A vacuum repair tech with professional diagnostic tools can spot the leak in a few minutes, get your vacuum breathing properly again, and keep you from turning a small airflow hiccup into a full-blown motor replacement. Sometimes the best vacuum repair—whether it’s for an upright or canister, or even a central vac—is just letting someone with the right eyes look at it.