A vacuum can have strong suction, a polished exterior, and a long list of specs—none of it means much if the filtration isn’t sealed. A sealed system keeps the airflow on a fixed path from intake to exhaust, forcing everything through the filters instead of letting it escape through seams, gaskets, or pressure points in the housing.

Machines built this way deliver more consistent results, especially in homes where vacuuming happens several times a week. You flip the switch on a bagged upright vacuum with sealed filtration, the motor settles into its normal tone, and the airflow behaves the way it did the week before.

Repair techs can often tell how well a vacuum is sealed just by opening the housing. When dust is pulled through unintended gaps, it coats the motor compartment, wiring channels, and any structural piece sitting downstream of the intake. It can be a little startling to see the inside of one of those machines—you open the shell and it feels like someone poured talcum powder into the electronics. You can end up with a machine that “looks” fine from the outside but behaves like it’s circulating fine debris back into the room.

A properly sealed unit also cuts down on the small variables that usually creep in over time. When the internal airflow stays contained, the motor runs under the load it was designed for, the filters do their job at full efficiency, and the brushroll doesn’t end up compensating for pressure loss. It turns routine cleaning into a simpler mechanical cycle: consistent airflow, stable suction, predictable results.

What Sealed Filtration Actually Does

Most people think of filtration as a static feature—a filter blocks particles, end of story. But filtration interacts with airflow, pressure, and the physical layout of the vacuum. A sealed system prevents air from taking shortcuts. Every cubic inch of airflow must travel through:

- the intake

- the bag or pre-motor filter

- the motor chamber

- the exhaust filter

Because the air isn’t bleeding out through gaps, the filters are able to work within their designed pressure range. That’s when you get more consistent performance instead of the decline that shows up in cheaper machines.

You can sometimes tell a system is leaking when you change a filter and realize the surrounding plastic looks dusty while the filter itself isn’t fully loaded. That imbalance means part of the debris found another path. So, if the filter’s clean but the internals look like a chalk mine, you know exactly where the airflow has been sneaking off to.

Where Leaks Develop in Non-Sealed Vacuums

A vacuum moves air under surprisingly high pressure, and the plastic shell has to contain all of that force while keeping the airflow on a fixed path. Any weak point in that enclosure becomes a leak channel over time. The most vulnerable spots tend to fall into a few predictable zones:

- The gasket around the bag or dirt bin

This is the first point of contact between the airflow and the housing. When the gasket hardens, compresses unevenly, or loses elasticity, fine dust slips around it instead of through the filtration media. Repair shops see this often: the gasket looks intact, but the groove it sits in has widened from years of pressure cycles. - Latch seams along the bag door or bin compartment

A latch that doesn’t pull the door tight puts the entire seal under strain. Even a millimeter of gap creates a pathway for air to bypass the bag entirely. You’ll sometimes find a gray outline along these seams—a literal trace of where the dust has been escaping. - Hose connection points

These joints flex constantly, especially on uprights, and the movement wears down the tolerance between the hose cuff and the port. When the fit loosens, air enters or exits at that junction instead of following the intended route through the filters. - The motor housing seam

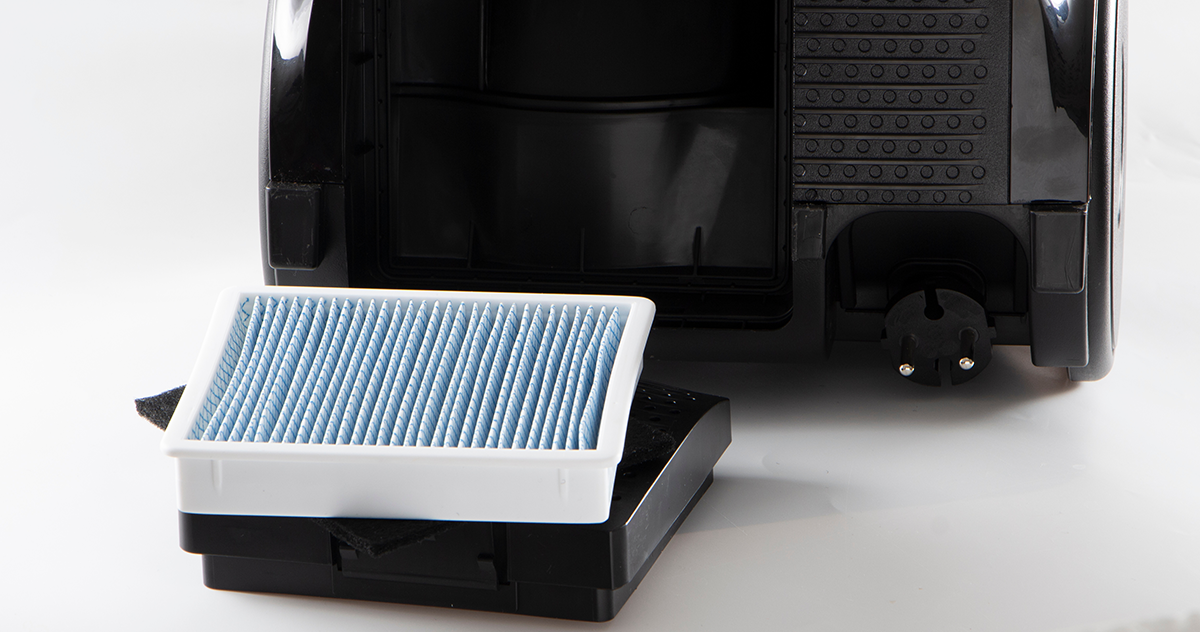

Motors generate heat and vibration, and both gradually work against thin or poorly aligned plastic. If dust manages to enter this section, it settles around the brushes and bearings, where it accelerates wear and reduces cooling efficiency. - Filter frames and their mating surfaces

Filters are only as effective as the frame holding them. If the frame sits crooked or the plastic warps slightly from heat, air finds its way around the media instead of through it. This can lead to clean-looking filters paired with a dusty interior.

Vacuum shells built from lightweight or flexible plastics struggle even more with long-term pressure cycles. As the structure flexes, gaps open just enough for the airflow to reroute itself. Once that happens, unfiltered air is drawn in near the intake and micro-particles are pushed out the exhaust. The machine continues to run, but the filtration behaves unpredictably.

If a machine relies on loose-fitting components or thin plastics, those areas widen with use. Once the seals weaken, the vacuum pulls in unfiltered air near the intake and blows out micro-particles near the exhaust.

In vacuum repair shops, two key symptoms show up again and again:

- Gray dust tracing up the interior walls of the housing—evidence that air skipped the filtration path.

- Filters that look “underworked”—they haven’t collected what they should have because the airflow wasn’t fully directed at them.

How Bags Strengthen the Sealed System

A bag reinforces the sealed path in a way that a rigid bin rarely does. Bags expand to match airflow pressure, creating surface contact that reduces bypass channels around the intake. As debris settles toward the bottom of the bag, the top section continues to pass air freely through the media. That’s part of why bagged uprights maintain steady suction longer than many bin-style vacuums.

The material of the bag plays a major role here. High-grade HEPA or S-Class bags capture extremely small particles without collapsing airflow, which is exactly what the pillar article discusses. When that filtration media is paired with a sealed housing, the vacuum performs like a controlled indoor air cleaning system while it’s running.

How a Sealed System Helps the Motor Run Longer

A motor is designed to operate with a certain amount of resistance. When dust leaks into the motor housing, it affects cooling, airflow, and the bearings. Over time, the motor has to work harder to push air through debris it was never supposed to encounter. This is why some vacuums burn out early even when the user follows the filter schedule.

Sealed filtration systems reduce internal contamination, keeping the motor breathing the way the engineers intended.

The difference is easy to see during a teardown. Sealed machines keep the motor compartment almost clean enough to wipe with a single cloth. Non-sealed machines often release clouds of fine dust when the shell opens.

Why Sealed Filtration Makes Carpet Cleaning More Effective

Strong carpet cleaning depends on a balance between suction and agitation. Suction removes loosened grit; agitation lifts it from the carpet base. When air leaks break the sealed path, suction becomes inconsistent, and the machine spends more energy compensating for lost pressure instead of focusing on debris removal.

Airflow inside a vacuum behaves a lot like any other pressured system: when the path leaks, the pressure differential collapses. That differential is what drives dirt upward from deep in the pile. Once it weakens, the vacuum stops pulling from the base of the carpet and starts skimming the upper fibers instead.

This results in “pressure loss across unintended gaps,” and in a carpet-cleaning context, it’s the point where embedded grit simply stops moving.

A sealed upright maintains airflow directly behind the brushroll, where it matters. Thick carpets especially benefit from this because the vacuum relies on steady airflow to pull dirt upward through the fibers. The physics here are simple enough, but easy to overlook. The vacuum needs a tightly controlled chamber behind the brushroll to create a low-pressure zone. That drop in pressure is what forces air (and debris) to accelerate upward through the fibers. If the system leaks, the vacuum can’t maintain that low-pressure area, and the lift effect collapses before the bristles can do their job.

Indicators That a Vacuum Likely Uses a True Sealed System

Most brands claim “sealed filtration,” but you can verify it by checking a few structural cues:

- Rigid housing—prevents flex that creates leak points

- Thick neoprene or silicone gaskets—form tight seals around filters and bag doors

- Full perimeter sealing—not just a single strip of foam

- Locking filter frames—designed to compress the gasket rather than loosely sitting in place

- Airtight hose ports—no wobble, no play

- Uniform bag door compression—especially on high-suction machines

If any of these components look thin, loose, or partially exposed, the filtration likely won’t behave the way the marketing suggests.

Who Benefits Most From Sealed Filtration?

A sealed system adds value for anyone who…

- …vacuums frequently

- …deals with fine dust, dander, or seasonal allergens

- …uses a vacuum on medium-to-deep carpet

- …wants predictable filtration performance

- …prefers machines that stay dependable with less frequent servicing

It’s also ideal for households where someone reacts strongly to airborne dust. Even with careful emptying, unsealed systems release more micro-particles than sealed ones.

How to Keep a Sealed Vacuum Cleaner Performing Like New

A sealed filtration system only works as intended when every component stays aligned and airtight. These habits keep the airflow path stable and prevent slow leaks from developing over time:

- Replace the bag before it reaches the top third of its capacity.

Airflow drops sharply when debris reaches the upper portion of the bag, and the extra pressure stresses the gasket around the bag door. - Clear the brushroll regularly.

Hair, thread, and packed fibers raise resistance at the intake, which forces the motor to compensate and increases internal pressure on seals. - Seat filters fully against their gaskets.

A filter that sits even slightly off-center creates a bypass channel that fine dust can slip through. - Inspect the housing for hairline cracks.

Impacts around the baseplate or bag compartment can shift panels just enough to break the seal under suction. - Schedule periodic tune-ups.

Technicians typically catch worn belts, loose seals, and aging bearings before they create airflow issues or motor strain.

Even a well-designed sealed system can lose efficiency if these small details slide. Keeping the airflow path clean and mechanically tight preserves the vacuum’s filtration performance over the long run.

A lot of long-term performance comes down to how the internal tolerances age. Gaskets compress, latch points loosen, and plastic panels shift a fraction of a millimeter after enough heat cycles. This can change how pressure moves through the system. When the tolerances drift, the vacuum starts pulling air from places it shouldn’t, and repair may be needed.

Takeaway

Sealed systems are important because they stabilize everything the vacuum itself is trying to do. When the airflow stays contained, the filtration hits its actual efficiency rating, the motor runs in a cleaner environment, and the brushroll keeps enough pressure behind it to lift debris from the base of the carpet instead of skimming the surface.

Over time, controlled airflow makes a measurable difference in how predictably a vacuum performs. Machines with sealed filtration hold their pressure more consistently, avoid the fine dust drift that develops in unsealed housings, and usually need fewer internal cleanouts because the motor compartment stays cleaner. For anyone focused on long-term performance who wants to avoid short cycles of decline and troubleshooting, sealed filtration is an important design element that keeps the rest of the machine running as intended.